-

-

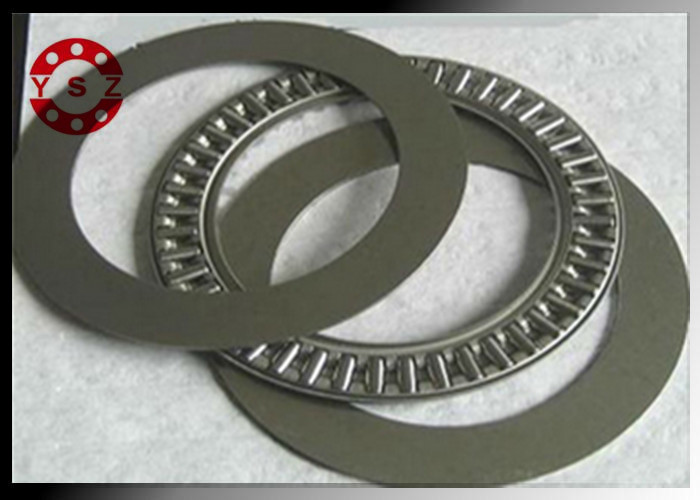

Product name: Low Noise Needle Roller Bearing K Series High Rotating Speed

-

-

Price: ASK

-

-

Post date: 2016-12-19

-

-

Stock Quantity: 1000

-

Low Noise Needle Roller Bearing K Series High Rotating Speed

1. High speed, High Precision, Low Noise, Long Service Life

2. Mainly withstand radial load

3. Customers' drawing or samples accepted

4. Heavy radial loads and high speeds

5. Military Specifications

6. Less vibration and noise

7. Small order accepted and sample accepted

.Structure Types

Needle retainer assembly K/K...ZW/K...D/K...ZWD type series:

Needle roller cage assembly components related to the size of the fixed axial bearing assembly use. When using high -speed condition when the retainer and the axial limit should be added to a washer through the heat-treated in order to avoid to maintain direct contact with the limit.

.Features

- Smaller cross-section leading to greated rigidity,higher load-carrying capacity & lower inertia of the needle roller bearings help size and weight reductions in machinery.

- Though they are less wide,their load carrying capacity is high and is most suitable for applications where the load is high & the radial space is less.

- Needle roller bearings,which are designed to withstand oscillation can operate under severe conditions & interchange with sliding bearings.

. Brand: TVB or per your demand, also can be made in your own brand.

Features of Needle retainer assembly :

a. High Precision and Rigidity

b. Ease of Assembly

c. Complete range of types

d. Needle retainer assembly bearings are used in automobile, rolling mill, mining, metallurgical industry,plastic machinery, etc.

e. Special Directions

- Bearing running clearance and inner-cutting roundness should be regulated according to different conditions.

- Machine tools should be used for press-in fitting or thermal fitting of the bearing

- Limited by plastic cages (suffixed with TN) and sealing-element material, operating temperature is -300C---+1000C.

- For general disposition design of bearings, refer to the relevant recommendation in the applied

technology of rolling

bearings.

f. Other advantages of Needle retainer assembly :

.Bearing material:bearing steel Gcr15 Chrome Steel

.Smooth movement,low friction,high rigidity and long life

.Nice appearance,complete product system

.We can make non-standard needle retainer assembly bearings according to clients samples of drawing

Details of Good Quality Wholesale Price K series needle retainer assembly

|

Name: |

Good Quality Wholesale Price K series needle retainer assembly |

|

Dimension: |

25*35*30mm |

|

Weight : |

65.5 g |

|

Inner Diameter : |

3-75mm |

|

Outer Diameter : |

5-83mm |

|

Material: |

bearing steel; chrome steel;stainless steel |

|

Cage: |

steel |

|

Clearance: |

C0,C2,C3,C4,C5 |

|

Precision Rating: |

P0, P6,P5,P4,P2 |

|

Vabration: |

Z1, Z2, Z3 |

|

Grease: |

per your request, such as SRL, PS2, and etc |

|

Package: |

single box or per your rquest |

|

Certification: |

ISO9001:2008, GB/T 19001-2008 |

|

Delivery Date: |

7-15 days upon receipt of 30% deposit |

|

Basic Tests: |

1.Assembly |

1.Internal Structure and Retainer Material Variation

C: Symmetrical roller, Stamped Steel retainer

CA: Symmetrical roller, one-pice brass cage

CTN1: Symmetrical roller, nylon cage

E: Third generation design. improved stress distribution; offer much longer service life than normal designs

Q: Bronze cage

MB: Symmetrical roller,Two-pice brass cage

EM: Symmetrical roller, Special alloy Integral cage.

2.External form chnage

K: Tapered bore bearing,taper is 1:12

K30: Tapered bore bearing,taper is 1:30

N: A snap ring groove on the outer ring

W33: There are three lubrication groove and three lubrication holes in the outer ring

3. Ring high-temperature tempering

S0: Work temperature up to 150 degrees Celsius.

S1: Work temperature up to 200 degrees Celsius.

S2: Work temperature up to 250 degrees Celsius.

S3: Work temperature up to 300 degrees Celsius.

S4: Work temperature up to 350 degrees Celsius.

4. Clearance

C0: Norminal clearance,omitted in destination

C2: Less than Norminal clearance

C3: Larger clearance than C0

C4: Larger clearance than C3

C5: Larger clearance than C3

C9: Special Clearance

About us:

. More than 20 years' experience in bearing manufacturing: the complete industry chain: continuous material suppliers,strong supply capacity, perfect system of freight forwarding.

. Customization production: size, modle, and package are per clients' demand.

. Realizable quality: we have our own factory, professional design team, strict quality control system and strong transportation cooperation.

. Professional: We can offer almost types of linear guide rail.Diameter 10-60mm,the Length can be produced according to your requirement.

. Delivery fast: Goods be sent out within 1 to 5 working days based on order quantity.

. First-class pre and after service: we ensure the well processing of the practice of our products for customers.

Please feel free to contact with us:

Tel: +86-0510-82021910

Fax: +86-0510- 82021910